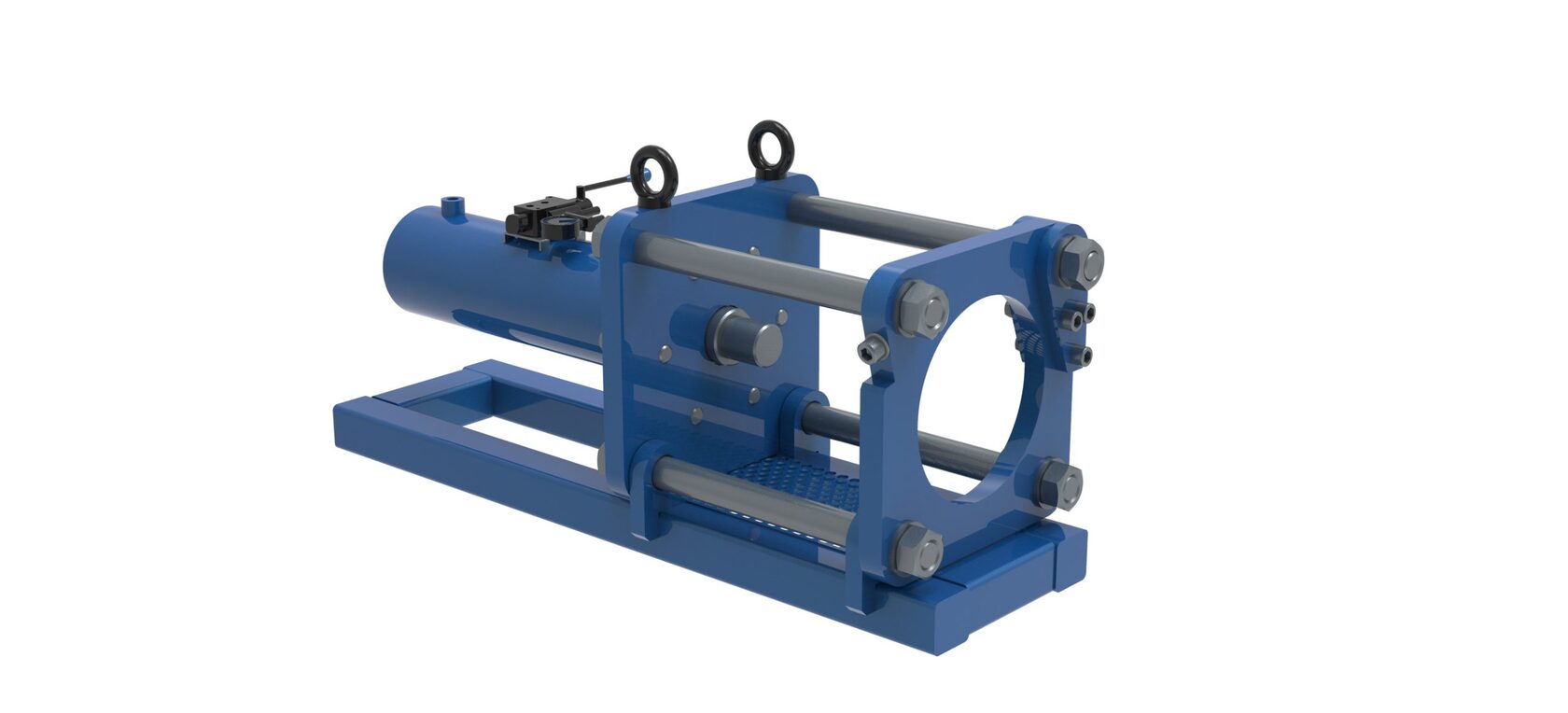

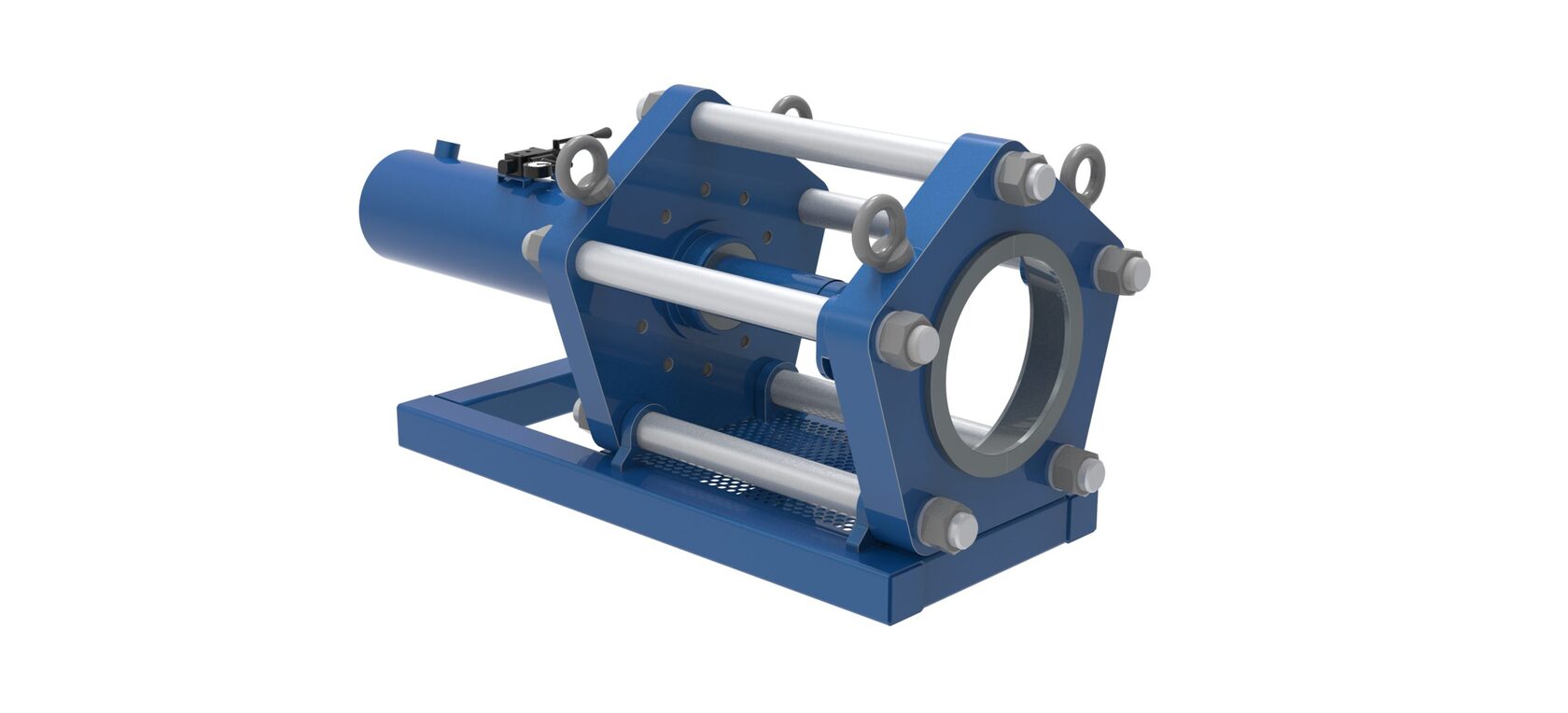

Hydraulic press PGS-3-250 for installation of fittings on pipelines DN 150mm, as well as installation of symmetrical fittings with a force of up to 30 tons.

Hydraulic press PG-3-250 for mounting fittings on pipelines up to DN 150 with a force of up to 15 tons

The end fittings are installed on the CTB in several consecutive stages - crimping on the inner surface, crimping on the outer surface.

The purpose of crimping is to permanently mold the walls of the end fitting to the pipe size. This operation ensures uniform tight compression of the pipe walls by the fitting, both on the inner and outer surfaces.

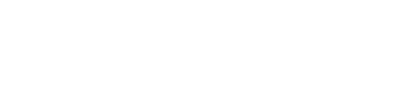

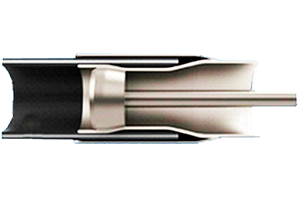

Principle diagram of pulling the fitting through the inner and outer surfaces of the fitting:

The purpose of crimping is to permanently mold the walls of the end fitting to the pipe size. This operation ensures uniform tight compression of the pipe walls by the fitting, both on the inner and outer surfaces.

Principle diagram of pulling the fitting through the inner and outer surfaces of the fitting:

- Quick installation of connections (30-45 minutes)

- Minimum amount of machinery

- 2-person crew

Fittings are installed on the pipeline using hydraulic presses, the appearance of which is shown below

Hydraulic press reinforced PGU-5-450 for mounting fittings on pipelines up to DN 200 with a force of up to 40 tons

FITTING INSTALLATION TECHNOLOGY

ADVANTAGES

Equipment for installation of fittings

Internal crimping

Crimping on the outer surface

TALK TO A REPRESENTATIVE

Interested in purchasing or learning more about LLc Promtechservice product? Fill out the form below to get in contact with Promtechservice representative.

Polymer reinforced pipelines, fittings and components, piping installation equipment. 2022

LLC PromTechService

Polymer reinforced pipelines, fittings and components, piping installation equipment. 2022

LLC PromTechService